ENIGMATY

INDUSTRY 4.0

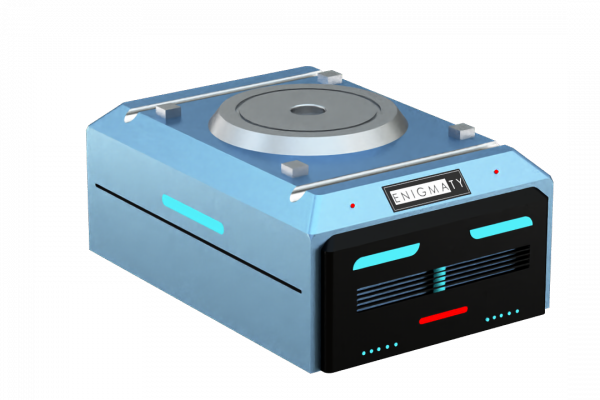

With intell-i Platform

What is Industry 4.0?

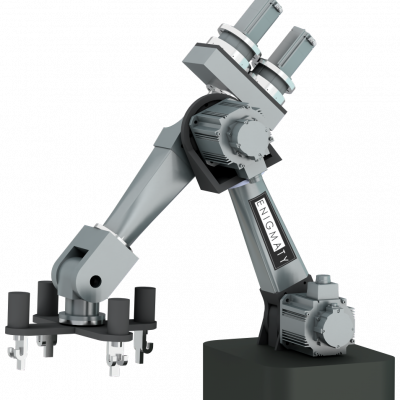

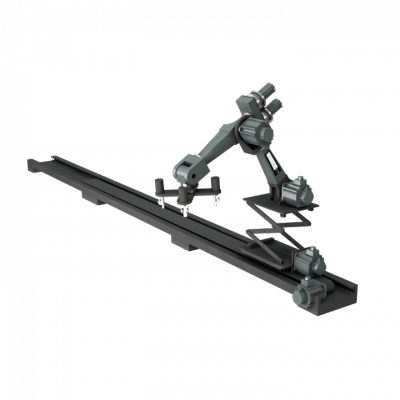

Also known as Industrial IOT, Industry 4.0 is 4th iteration in industrial revolution; with the help of cutting edge modern technologies like Artificial Intelligence, Advance Robotics, Powerful Software and Complex Computer Networks Industry 4.0 leverages the power of smart machines and real-time analytics which gives advantage of the data that machines have produced for years.

Current

Challenges

Factories face number of problems which can cause loss in your production, This can be solved by Industry 4.0 which are listed below

- Automation and Enterprise Systems – Operating and Working in Data Silos

- Data driven decisions not being adopted by management

- Lack of Integrated Operational Efficiency

- Lack of insight into machine

- Production line performance, production downtime and losses in real time.

- High reliance on manual and paper reports to determine productivity and plant performance

We can Solve

Your Problems

In this modern era manufacturing plants still have huge amounts of day-to-day manufacturing problems however Industry 4.0 can solve most of that problem like.

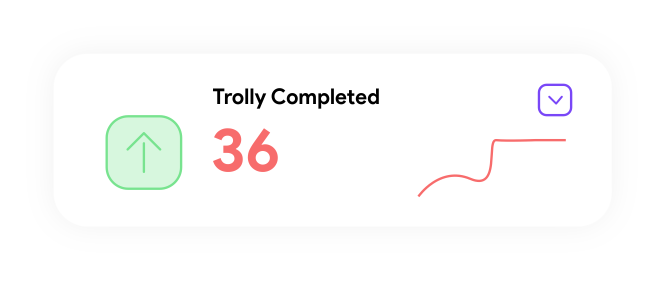

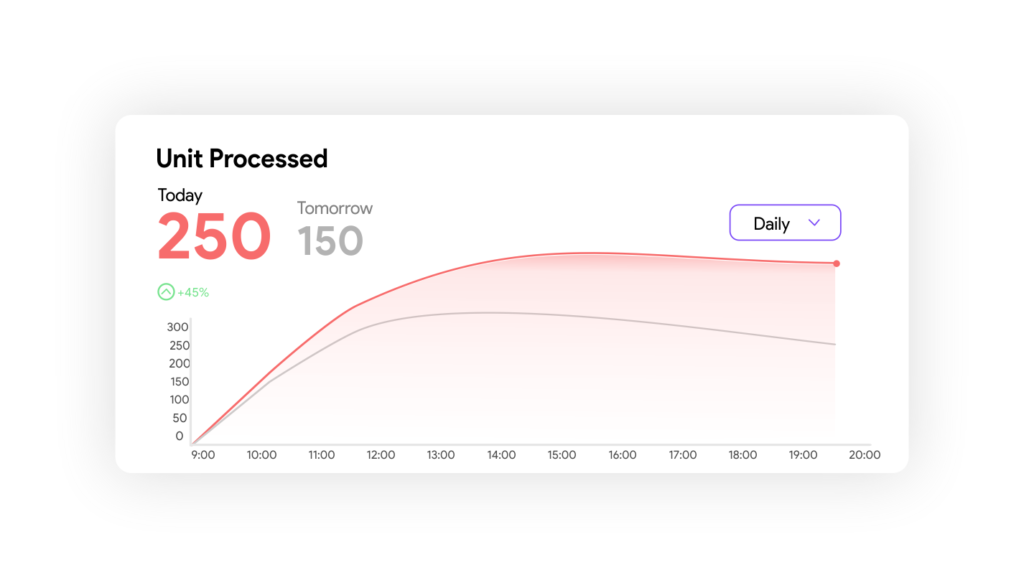

Real-Time Production Trends & Reports for immediate analysis

Predictive Analytics – Future Planning & Effect Insights

Smart Alerts – Custom Rule-based Alerting & Offline Monitoring

Fault Monitoring System

Quality Assurance System

Full Machine Automation And Rule-Based Decision

Production

Analysis

With analytics and statistics you can make your production more efficient with increase in reliability of your plant. With the help of Enigmaty’s intell - i industrial software you can get data like:

- Equipment Efficiency Analysis & Details

- Batch/Production Performance

- Production Loss Analysis

- Product-wise Efficiency and Wastage Analysis

- Operator Performance